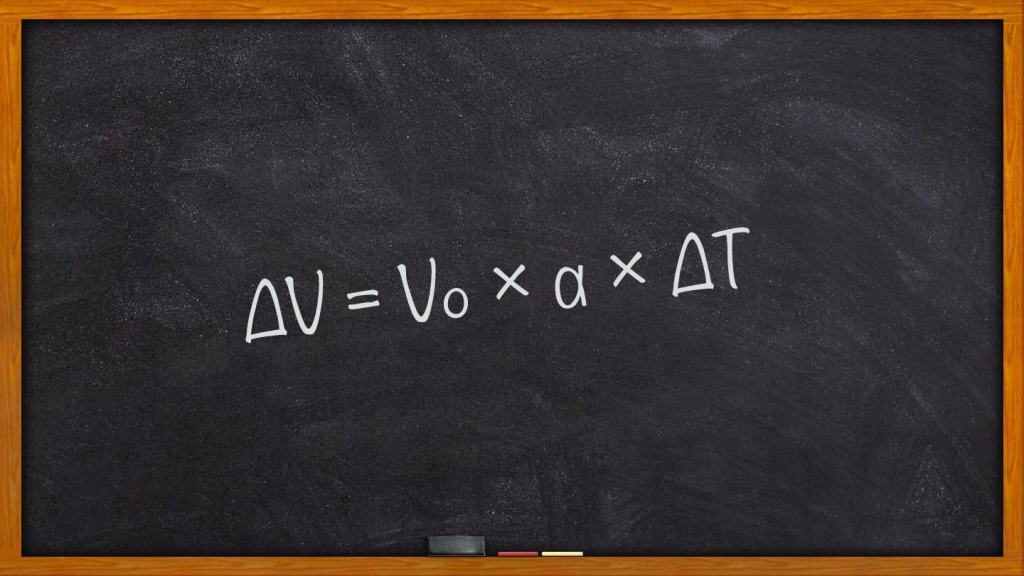

Principle of Ink Explosion: Thermodynamic Collapse of Ink System

Formula for Ink Expansion Coefficient

The change in ink volume follows the formula:

ΔV = V₀ × α × ΔT

Among them:

ΔV is the volume change

V₀ is the initial volume (approximately 0.5ml for standard pen refills)

α is the coefficient of thermal expansion of ink (1.2 × 10 ⁻ ³/℃ for water-based ink and 0.7 × 10 ⁻ ³/℃ for oil-based ink)

ΔT is the temperature difference (e.g. Δ T=25 ℃ when rising from 25 ℃ to 50 ℃)

Calculation Example:

Volume expansion of water-based ink at 50 ℃:

ΔV = 0.5ml × 1.2×10⁻³ × 25 = 0.015ml

(Exceeding the swelling space of the pen core by 0.01ml will cause ink explosion)

Failure Analysis of Key Components

Pen tip sealing ring: Silicone material begins to soften and deform when the temperature exceeds 60 ℃, resulting in a 300% increase in ink leakage rate

Ink bag material: LDPE plastic undergoes structural collapse after reaching the Vicat softening point of 75 ℃, causing internal pressure imbalance

Tail plug vent: When the air permeability of the ventilation membrane exceeds 0.5ml/min, air backflow will accelerate ink expansion

Global Map of Pen Explosion Areas

Climate Risk Level

Red alert area: including Dubai, Doha and other places, with an annual average temperature of 38 ℃ and a high ink explosion rate of 27%

Orange warning areas: such as Singapore and Bangkok, with an annual average temperature of 32 ℃ and an ink explosion rate of 15%

Yellow warning area: covering Miami, Mumbai and other places, with an annual average temperature of 28 ℃ and an ink explosion rate of 8%

Deadly Period during Transportation

Shipping Containers: The internal temperature of deck level containers can reach 72 ℃, and continuous exposure for more than 48 hours will cause structural damage

Middle East Land Transportation: Truck cargo containers reach a peak temperature of 61 ℃ during noon hours, with an average daily exposure time to high temperatures exceeding 6 hours

Storage Black Hole: The temperature gradient difference between the shelves of non temperature controlled warehouses in summer can reach 22 ℃, with a significant temperature difference between the top and bottom layers

Five Lines of Defense for Explosion-Proof Technology

Ink Formula Upgrade

Nano Silica Addition: reduces the ink expansion coefficient from 1.2 × 10 ⁻ ³/℃ to 0.4 × 10 ⁻ ³/℃

Phase Change Microcapsule Technology: activates endothermic reaction at 35 ℃, and can absorb 80 joules of expansion energy per gram of material

Structural Strengthening Design

Spiral Buffer Ink Bag: Provides 0.03ml of redundant expansion space through a special winding structure

Ceramic Based Sealing Ring: made of silicon carbide ceramic material, with temperature resistance increased from 60 ℃ to 120 ℃

Packaging Black Technology

Aerogel Thermal Insulation Layer: 2mm thick aerogel material can reduce the internal temperature of the package by 14 ℃ and increase the cost by 18%

Phase Change Energy Storage Box: Paraffin based material absorbs heat during heating, achieving active temperature control of 21 ℃ and increasing cost by 25%

Intelligent Temperature Control Label: using thermochromic ink, the label changes from green to red when the temperature exceeds the standard, increasing the cost by 5%

Logistics Control System

Three Principles of Container Loading:

1. Maintain a distance of at least 30cm between the goods and the side wall of the container

2. Leave a 10cm heat dissipation channel between each pallet of goods

3. Mandatory use of white reflective containers to reduce heat absorption rate

Transportation Monitoring: Each container is equipped with a temperature recorder, and the data is uploaded to the cloud in real-time

Terminal User Guide

Storage three elements:

1. Avoid light storage: UV rays can increase the aging rate of plastics by three times

2. Standing upright: tilting more than 45 degrees will cause the ink gravity to compress the pen tip sealing ring

3. Temperature zoning: Install a constant temperature stationery storage cabinet in the office area (recommended 25 ± 2 ℃)

Emergency Response Plan for Ink Explosion

On Site Rescue Steps

1. Emergency Isolation: Wrap contaminated documents in aluminum foil sealed bags to prevent secondary infiltration

2. Low Temperature Curing: Place the pen in a car refrigerator at 4 ℃ and refrigerate for 10 minutes to increase the ink viscosity by 5 times

3. Professional Cleaning: Use 95% concentration ethanol solvent, combined with non-woven fabric for one-way wiping (do not circle)

Claim Evidence Chain

Core Evidence:

Third party temperature recorder data (must comply with ISO 9001 standard)

Panoramic monitoring video of container loading process (at least 1 frame per second)

Material defect report issued by SGS (including measured expansion coefficient)

Supporting Evidence:

The temperature clause in the procurement contract (it is recommended to clearly indicate “transportation temperature ≤ 50 ℃”)

Special risk coverage in logistics insurance policies

If this article is helpful to you, then we will be very happy!

Here we recommend our stationery export website: www.peninkstationery.com

If you need to import stationery from China, please click on our website and contact us.

Aw, this was a very nice post. In thought I wish to put in writing like this moreover – taking time and precise effort to make an excellent article… but what can I say… I procrastinate alot and in no way appear to get one thing done.

Thank you for your praise of my article! As for what you mentioned—it’s okay, even if you ‘temporarily don’t want to,’ that is the most genuine state you are in right now. Please feel free to embrace yourself in any state!