Metal Stationery

Example: Ballpoint Pen/Metal Parts of Ballpoint Pen

Recommended process:

▨Laser engraving

- Technical parameters:

Laser type: Fiber optic (1064nm)/CO ₂ (10.6 μ m)

Carving depth: 0.08-0.3mm adjustable

Resolution: 1000-5000 DPI - Advantages: Permanent marking, alcohol resistant wiping for over 500 times

- Limitations: Only applicable to reflective materials such as stainless steel/titanium alloy

Plastic Stationery

Example: Plastic Pen Holder/Folder

Recommended process:

▨UV digital printing

- Ink parameters:

Viscosity: 12-15 CPS (25 ℃)

Curing energy: 800-1500 mJ/cm ² - Advantages: Full color printing, supporting gradient colors

- Limitations: Not resistant to acetone wiping (<20 times)

▨ Transfer printing

- Technical parameters:

Rubber head hardness: 30-80 Shore A

Printing pressure: 2.5-4.5 kg/cm² - Advantages: Strong adaptability to curved printing

- Limitations: Single color/spot color dominant

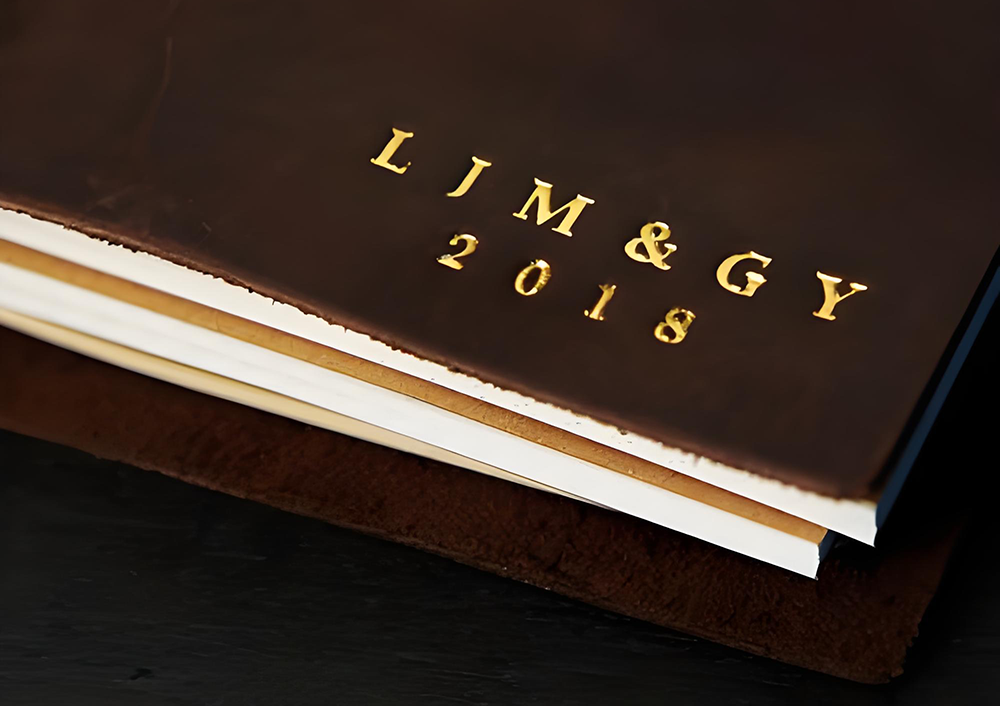

Paper Stationery

Exmaple: Notebook Cover/Note Paper

▨ Hot stamping/Silver stamping

- Material parameters:

Thickness of hot stamping foil: 12-25 μ m

Temperature: 120-160 ℃ - Pressure: 15-30 kg/cm ²

- Advantages: High end texture, strong wear resistance

▨ Strike Convex/Press Concave

- Mold parameters:

Bronze plate depth: 0.3-1.2mm

Pressure: 40-80 tons - Advantages: Three dimensional tactile sensation, no need for ink

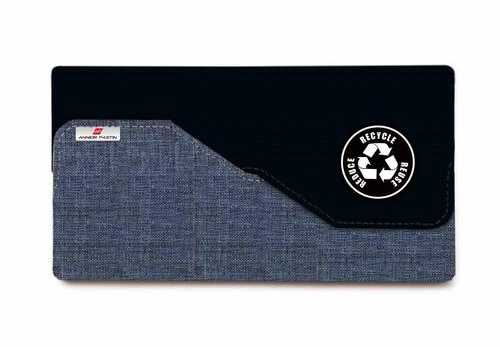

Textile Stationery

Example: Pen case/Backpack

▨ Screen Printing

- Screen parameters:

Mesh size: 120-200 mesh (cotton fabric)/300-420 mesh (synthetic fiber)

Rubber scraper hardness: 65-75 Shore A - Advantages: Thick ink layer coverage, bright colors

▨ Digital Direct Spray

- Technical parameters:

Nozzle accuracy: 1200 × 1200 DPI

Pre treatment solution: cationic agent containing 8-12% solid content - Advantages: No plate fee, supports complex patterns

Silicone Stationery

Example: Rubber/Grip Pen Cover

▨ Liquid Silicone in Mold Molding (LSR)

- Process arameters:

Mold temperature: 160-200 ℃

Sulfurization time: 15-40 seconds - Advantage: Logo and product integrated molding

▨ Laser Marking

- Technical parameters:

Wavelength: 355nm UV laser

Power: 3-5W - Advantages: No contact, no damage to materials

Process Selection Decision Tree

Selection steps:

1 Determine the material of the product → 2 Evaluate Logo Size Accuracy → 3 Accounting budget/MOQ

→ If you need full-color+small batch → Choose UV digital printing

→ If permanent marking is required → Select laser engraving

→ If you need a three-dimensional effect → Select hot stamping/embossing

→ If flexible surface is required → Choose screen printing

Contact us to start your stationery importing right now!

📞 +86 579 8158 8888

🌐 www.peninkstationery.com

✉️ 771629975@qq.com