China is an important base for the global stationery manufacturing industry, attracting a large number of international buyers with its rich product variety, mature supply chain, and cost-effectiveness advantages. However, when purchasing stationery for the first time in China, there may be pitfalls due to cultural differences, unfamiliar industry rules or processes. The following are key considerations for first-time buyers:

1. Pre preparation: Clarify requirements and conduct market research

- Clearly define the procurement objectives

– Determine the category of stationery (such as writing tools, paper products, office supplies, or creative stationery), budget, order quantity (MOQ), and quality standards (such as environmental certification, child safety standards, etc.).

– Understand the consumer preferences of the target market. - Study the stationery industry belt in China

– China’s stationery production is concentrated in Ningbo, Zhejiang (brand bases such as Deli and Chengguang), Shantou, Guangdong (stationery gift cluster), Yiwu (small commodity wholesale center) and other places. Different regions have different advantageous product categories, and locking in the purchasing area in advance can improve efficiency. - Pay attention to industry exhibitions

– Participate in China International Stationery and Office Supplies Exhibition, Canton Fair and other exhibitions, directly contact factories and high-quality suppliers, conduct on-site inspections and establish contacts.

2. Supplier screening: Avoiding cooperation risks

- Beware of the “low price trap”

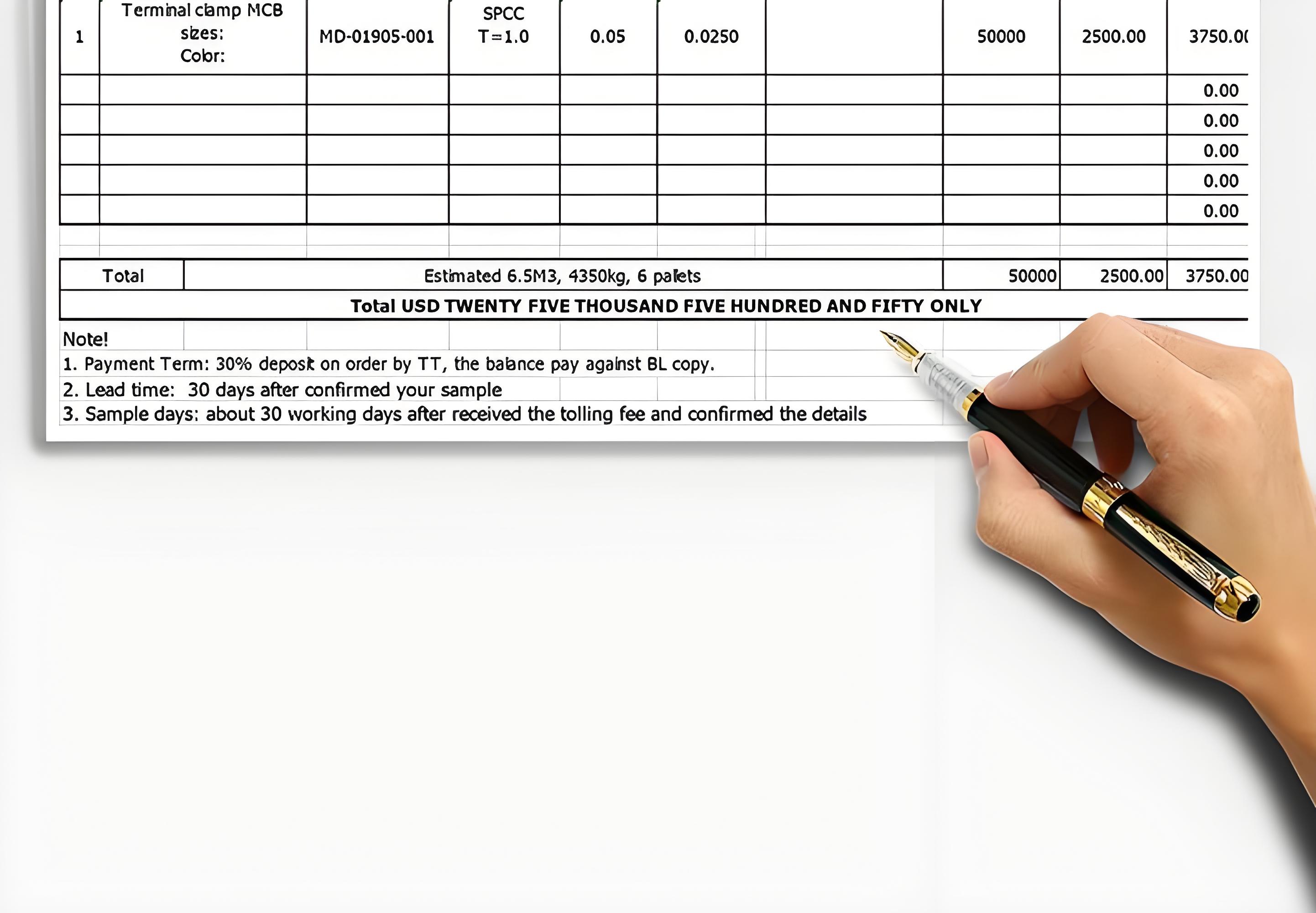

– A quote that is too low may conceal quality issues. Request the supplier to provide a detailed quotation, specifying material costs (such as pen ink type, paper weight), processing fees, and packaging costs. - Sign a clear contract

– The contract should specify product specifications, inspection standards, delivery time, payment method (recommended to use T/T 30% deposit+70% final payment or letter of credit), breach of contract clauses, etc. Chinese contracts require professional translation and verification.

3. Quality control: avoid goods not matching the board

- Strict sample testing

– Request to send bulk samples (non refined samples) for testing actual performance (such as pen tip fluency and notebook paper tear resistance). Some countries require compliance with specific certifications (such as EU EN71, US ASTM). - Third party inspection services

– For large orders, it is recommended to entrust SGS, BV and other institutions to conduct mid-term production and pre shipment inspections, with a focus on checking color differences, dimensional tolerances, and packaging integrity.

4. Logistics and payment: Ensuring smooth processes

- Choose a suitable transportation method

– Small quantities can be shipped via international express delivery (DHL/FedEx), while bulk goods can be shipped by sea (FOB/CIF terms). Confirm tariff policies in advance (such as the possible imposition of environmental taxes on plastic products in Europe and America). - Cooperate with reliable freight forwarders

– Process customs clearance documents (such as packing lists, invoices, and certificates of origin) through freight forwarding companies, and prioritize agents with experience in transporting stationery to avoid moisture or compression damage to the goods. - Exchange rate and payment security

– Using Chinese yuan (CNY) for settlement can reduce the risk of exchange rate fluctuations.

5. Cultural Communication and Long term Cooperation

- Establish a trust relationship

– Chinese suppliers value long-term cooperation and can prepare small gifts (such as local specialties) when meeting for the first time. When communicating, be patient and avoid directly rejecting the other party’s proposal. - Make good use of local resources

– Hiring translators or entrusting procurement agencies to assist in negotiations, especially in bargaining and dispute resolution, can greatly improve efficiency through professional communication. - Pay attention to the production cycle

– To avoid long holidays such as Spring Festival (January February) and National Day (October 1-7), the factory may shut down. Peak season orders need to be placed 3-6 months in advance.

6. After sales and return orders

- Retain spare samples

– Retain the sealed sample as the basis for after-sales disputes, clarify the return and exchange conditions (if the defect rate exceeds 5%, free replenishment is required). - Maintain supplier relationships

– Timely feedback on market sales situation, and strive for better prices or customized services (such as logo printing, mixed packaging) when returning orders.