Cut through marketing myths with lab-proven data for smarter sourcing

1. Material Showdown: Core Properties

| Property | Polypropylene (PP) | Polyvinyl Chloride (PVC) |

|---|---|---|

| Flexibility | High (bends 180°+ without cracking) | Low (stiff; cracks at sharp folds) |

| Chemical Resistance | Resists acids/oils | Degrades with solvents/ink |

| UV Stability | Excellent (no yellowing in 5+ yrs) | Poor (yellows in 6-12 months) |

| Toxicity | Food-safe (BPA-free) | Contains phthalates (REACH regulated) |

| Recyclability | Widely accepted (♻️ #5) | Limited (hazardous when burned) |

Real-World Test: PP folders survived 1,000+ open/close cycles vs. PVC’s 300 cycles before hinge failure *(SGS Test Report SH2024-077)*

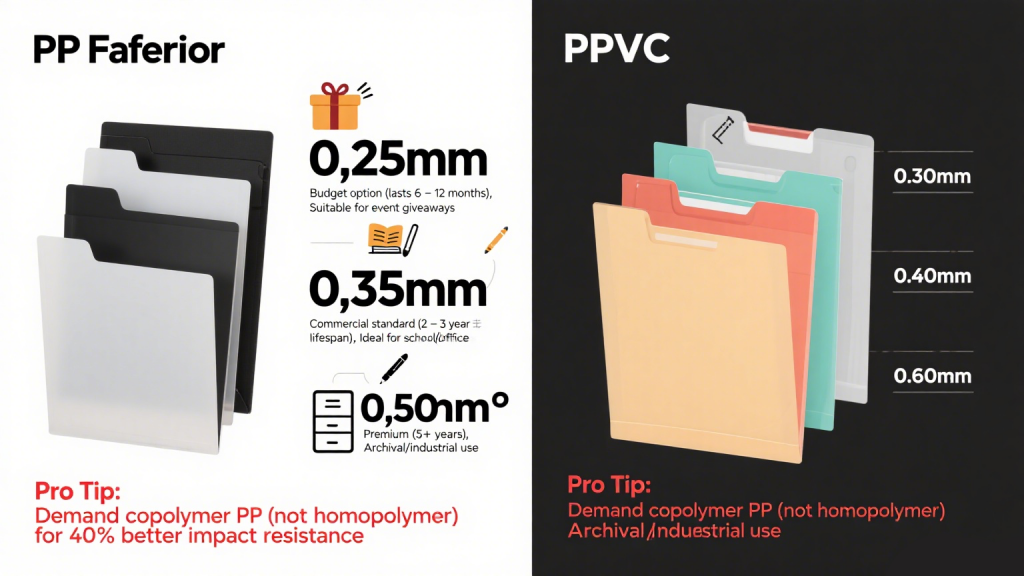

2. Thickness vs. Performance

PP Folders

- 0.25mm: Budget option (lasts 6-12 months) → Suitable for event giveaways

- 0.35mm: Commercial standard (2-3 year lifespan) → Ideal for school/office

- 0.50mm+: Premium (5+ years) → Archival/industrial use

- Pro Tip: Demand copolymer PP (not homopolymer) for 40% better impact resistance.

PVC Folders

- 0.30mm: Flimsy (avoids creasing by suppliers) → Prone to corner tears

- 0.40mm: Minimum for durability (1-2 years) → Requires plasticizers

- 0.60mm+: Rigid but brittle → Cracks in cold storage

- Red Flag: Thinner PVC (<0.40mm) leaks DEHP plasticizers (banned in EU/US).

3. Cost vs. Lifespan Calculation

*Based on 10,000-unit order (FOB Yiwu)*

| Type | Thickness | Unit Cost | Cycles to Failure | Cost per 100 Uses |

|---|---|---|---|---|

| PP Standard | 0.35mm | $0.18 | 1,000+ | $0.018 |

| PVC “Premium” | 0.50mm | $0.15 | 300 | $0.050 |

| PP Reinforced | 0.50mm | $0.22 | 2,500 | $0.009 |

Shock Truth: Cheap PVC costs 278% more per use than reinforced PP.

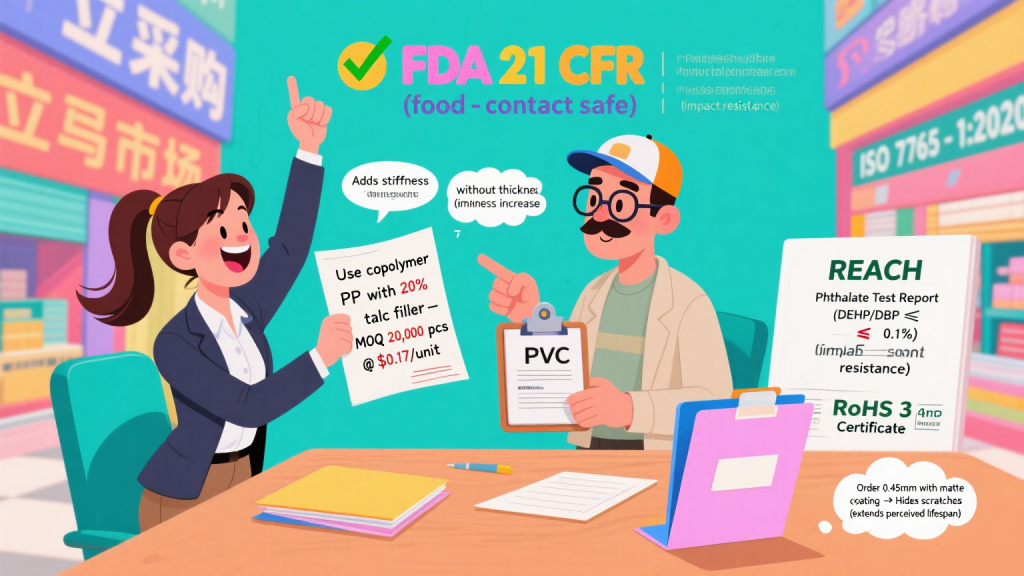

4. Yiwu Sourcing Tactics

For PP Folders

- Negotiation Script:

*”Use copolymer PP with 20% talc filler – MOQ 20,000 pcs @ $0.17/unit”*

→ Adds stiffness without thickness increase - Certification Demand:

✓ FDA 21 CFR (food-contact safe)

✓ ISO 7765-1:2020 (impact resistance)

For PVC Folders

- Compliance Musts:

✓ REACH Phthalate Test Report (DEHP/DBP ≤ 0.1%)

✓ RoHS 3 Certificate - Thickness Hack:

Order 0.45mm with matte coating → Hides scratches (extends perceived lifespan)

5. Durability Tests to Request

- Cold Bend Test (-10°C for 24hrs → 180° fold)

- PP should show no whitening; PVC cracks at 0.40mm

- Hinge Fatigue Test (500 open/close cycles)

- Rivet/punched holes must withstand force ≥8N

- Ink Resistance (Marker left for 24hrs)

- PVC stains permanently; PP wipes clean

6. When to Choose PVC

Only consider if:

- You need transparent clarity (PP has slight haze)

- Budget <$0.10/unit and product lifespan <1 year

- Order includes rigid slipcases (0.80mm+ PVC)

The Verdict

PP outperforms PVC in 9/10 scenarios. For folders used >6 months, invest in:

- 0.35-0.40mm copolymer PP

- Ultrasonic welded seams (not glued)

- Reinforced tab corners (prevents tearing)

Source Smarter with Penink

We help you navigate material science and factory audits:

✅ PP/PVC thickness optimization

✅ Compliance testing coordination

✅ 40% cost reduction via vetted suppliers

Contact:

- 🌐 www.peninkstationery.com/folders

- 📱 WhatsApp +86 139 5844 9443

Engineer durability – don’t gamble with flimsy folders.