The frustrating snap of a mechanical pencil lead is a universal experience, but its cause is rarely a mystery. For buyers and sellers, understanding the root cause is critical to sourcing reliable products and minimizing returns. The breakage is almost never a single point of failure but a complex interaction between the lead, the mechanism, and user habits.

Here’s how to diagnose the problem and specify higher-quality products from your suppliers.

The Two Culprits: A Breakdown

1. Lead Quality (The Most Common Cause)

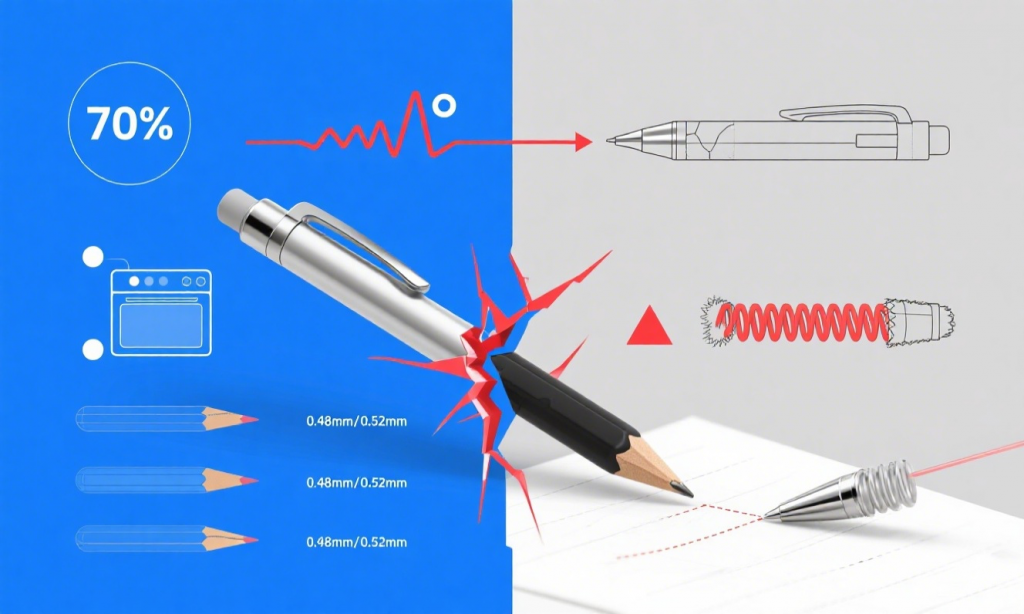

Poor quality lead is the prime suspect in over 70% of breakage cases, according to factory QC data. The issues are often invisible to the naked eye.

- Inconsistent Composition: Low-grade graphite is mixed with inferior binders like low-quality clay or excessive wax. This creates weak points and bubbles inside the lead.

- Improper Curing: Leads are baked in ovens to harden. Incorrect temperature or time leads to leads that are too brittle or too soft.

- Micro-Fractures: Rough handling during packaging and transport can create tiny cracks that cause the lead to snap under the slightest pressure.

- Diameter Inaccuracy: A lead advertised as 0.5mm might actually be 0.52mm or 0.48mm, causing it to jam or snap in the tip.

2. Pencil Mechanism (The Engineering Failure)

A perfect lead will break in a flawed mechanism. The flaws are often in the subtle details of manufacturing.

- Misaligned Tip (Nose Cone): The tip is the guide tube that protects the lead. If it is bent, even slightly, or not perfectly concentric with the mechanism, the lead will be stressed and break upon exit.

- Weak or Worn Clutch: The clutch is the metal gripper that holds the lead. If it doesn’t grip evenly or has sharp, burred edges, it will crush the lead instead of holding it.

- Faulty Internal Spring: The spring that advances the lead must provide smooth, consistent pressure. A cheap, overly strong, or jerky spring will shatter the lead from within the barrel.

- Poor Tip-to-Paper Feedback: A wobbly or poorly machined tip doesn’t provide stable support for the lead as you write, allowing it to bend and snap.

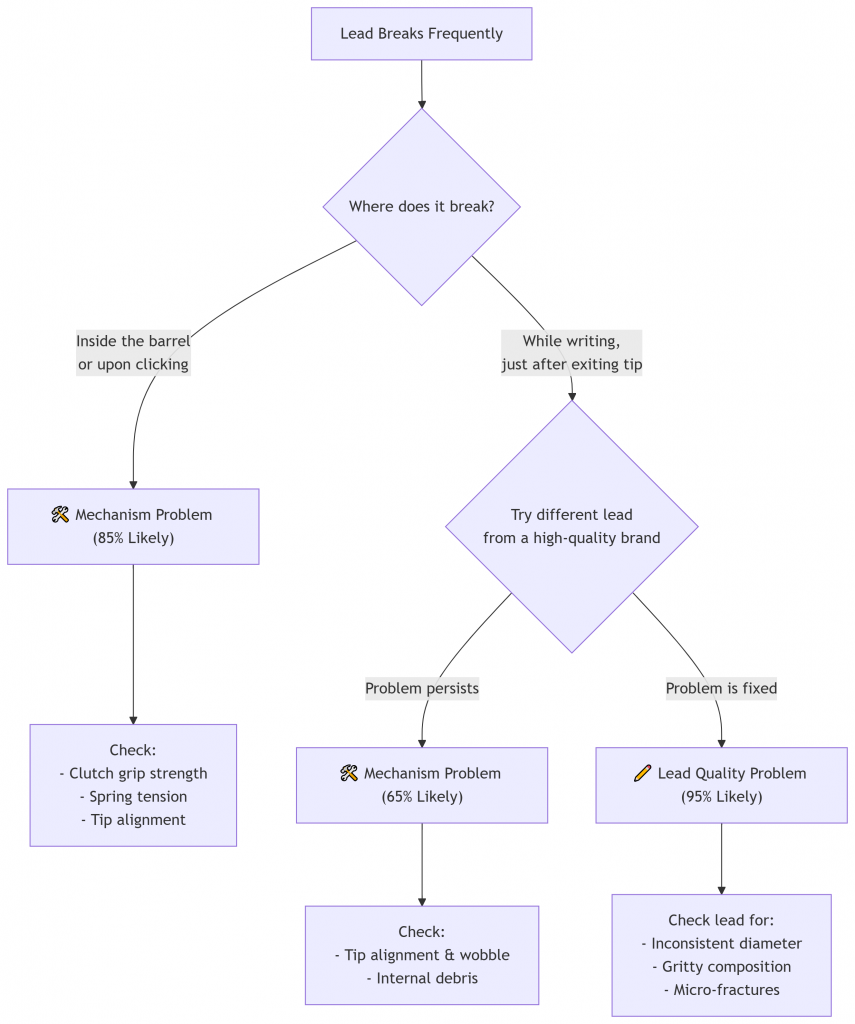

How to Diagnose the Problem: A Practical Guide

Use this simple flowchart to identify the root cause:

The Sourcing Perspective: Questions to Ask Your Yiwu Supplier

To avoid these issues, move beyond price and ask technical questions:

About the Lead:

- “What is the graphite-to-clay ratio?” (Higher graphite = smoother but softer; more clay = harder but more brittle).

- “What is the diameter tolerance?” (Demand ±0.02mm for 0.5mm lead).

- “Can you provide a break-strength test report?” (A standard ASTM test).

- “Is the lead polymer-infused?” (Polymer leads, like NanoDia, are more flexible and resistant to breakage).

About the Pencil:

- “What material is the clutch?” (Brass is superior to zinc alloy).

- “How is the tip secured?” (A threaded metal tip is better than a pressed-in one).

- “What is the tip wobble tolerance?” (It should be negligible).

- “Can you provide a video of the lead advance mechanism in operation?”

The Verdict

While both are contributing factors, poor lead quality is the most frequent offender, especially in price-sensitive market segments. However, a truly terrible mechanism will break even the best lead.

For buyers, the solution is to source leads and pencils as a matched system from a supplier that controls both quality standards. The marginal cost increase for polymer leads and a brass clutch mechanism results in a dramatically superior product that enhances brand reputation and reduces customer complaints.

Your Next Step in Yiwu Sourcing:

Stop dealing with broken leads and frustrated customers. Penink Stationery partners with factories that use precision-grade components and provide full quality certification.

👉 Take Action Today:

- Our Website: www.peninkstationery.com

- Technical Sourcing Support: WhatsApp +86 139 5844 9443